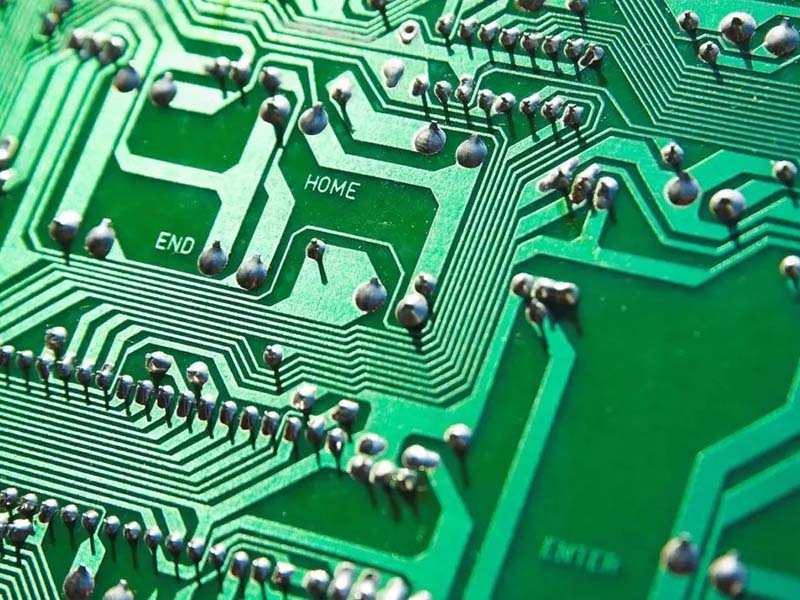

How Much Does It Cost To Get A PCB Assembly?

Technologists and Engineers involved in a project’s design and development phase need to be aware of the costs associated with turning their initial idea into a final product. Charges related to PCB manufacturing are impacted by several variables, including design complexity and product performance. For example, depending on how intricate the job you wish to produce is, PCB assembly costs will change. In addition, the accuracy of your design and the quality of the componentry will affect the PCB assembly cost.

So, to alleviate consumer anxiety slightly, Eashub discloses the price of purchasing a PCB assembly.

PCB assembly cost

- Cost of PCB assembly

The factors listed below, described in more detail, determine a PCB assembly cost.

- The price of the materials

- The cost of PCB manufacture

- The cost of testing and assembling PCBs

- The cost of processing SMT (SMD patch plus DIP post-welding).

- Costs of PCB manufacturing and PCB component.

Depending on the application, there are single-sided, double-sided, and multi-layer PCBs. The most popular double-sided PCB materials are FR-4, CEM-3, and others with thicknesses ranging from 0.6mm to 3.0mm. Significant variations in copper thickness are also possible. PCBs can be made in various methods, and the selected production process is one of the critical factors affecting PCB assembly cost.

- Complexity of PCB

The price will vary if the PCB specifications differ, but the materials and manufacturing processes are the same. The production cost will alter if the material, processing, and aperture are identical but the line width and distance on the PCB are different.

- Several PCB manufacturers

Even though two PCBs may have identical qualities, different PCB makers may charge differently. As a result of the variance in costs among manufacturers’ procurement, management, technology, and manufacturing methods, each of these variables will impact PCB assembly cost.

- The cost of purchasing the equipment

The PCB assembly patch processing required the purchase of several components. The producer of PCB assembly will swiftly distribute stock or buy things from your list. Reduced procurement costs and faster, more accurate component sourcing has resulted from developing an entire supply chain between PCB assembly manufacturers and component suppliers.

- Cost of PCB Assembly tests done.

Each PCB component typically costs $0.3 to examine during PCB assembly, while PCB assembly and packaging cost roughly $0.15. As there are more orders, testing costs for PCB assembly will fall.

How can we cut the price of PCB Assembly?

- Users can choose a reliable PCB assembly manufacturer like ours for proofing if they require a small quantity of PCB assemblies. Each PCB assembly manufacturer has unique advantages, a distinct emphasis, and process capabilities.

- When choosing a source for components, look for one with stock. Alternately, enquire as to whether the PCB assembly company has any store or if they must obtain their supplies elsewhere.

- Choosing the PCB bare board manufacturing process is crucial. When choosing PCB elements, it is best to pick common materials if there are no specific process requirements.

- Several producers can lower part costs if the volume is high. However, many PCB assembly companies must bill separately for assembly testing and production charges. Consumers must know the price of assembly testing before signing a contract with a PCB assembly company.

Conclusion

Based on their extensive PCB assembly knowledge, EASHUB analyses the cost of a PCB Assembly and offers cost-cutting PCB assembly solutions. However, there are ways to lower PCB assembly costs without sacrificing the quality of the finished product. If you compromise the quality of your products to lower the price, you risk irreversible harm. So, if you are looking into PCB assembly cost, Eashub is the best source to help you with this.