Can an Ultrasonic Crusher be used to Separate Organelles?

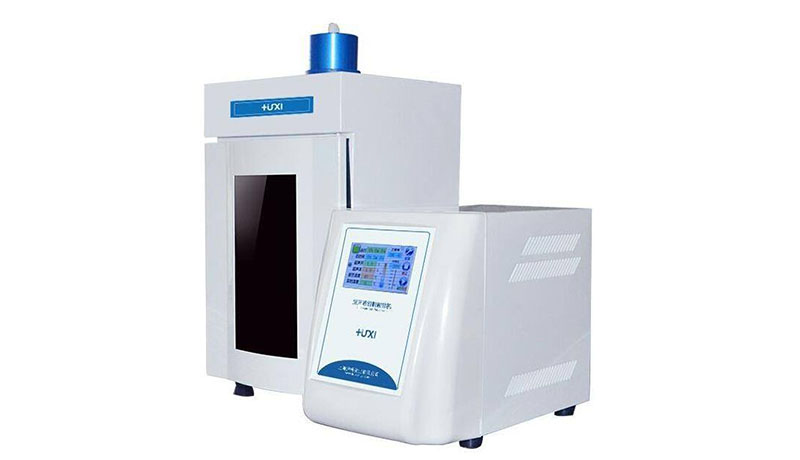

What is a Cell crushing ultrasonic instrument

An ultrasonic cell crusher is also called an ultrasonic microwave synergistic extraction instrument, an ultrasonic cell lysis instrument, or an ultrasonic nanomaterial pulverizer. Ultrasonic cell crushers employ powerful ultrasound to induce cavitation and treat material. It can be used for crushing cells, bacteria, viruses, animal and plant tissues; emulsification; separation; homogenization; extraction; defoaming, cleaning; preparation of nanomaterials; dispersion and acceleration of chemical reactions in microbiology, biochemistry, physics, surface chemistry, medicinal chemistry, zoology and other fields.

Crushing ultrasonic instrument Principle

The ultrasonic cell pulverizer breaks solid particles or cell tissue in liquid using cavitation and mechanical action. When ultrasonic waves propagate in liquid, they create cavities. The high-frequency vibration causes these cavities to enlarge and explode. When the vacuum cavity is blasted, instantaneous pressure can reach hundreds of atmospheres. When the cavity partially explodes, neighboring particles can fracture. Due to the ultrasonic wave’s intense vibration in the liquid, the material moves quickly, colliding with each other or the device’s wall.

An ultrasonic generator and a transducer make up a cell crusher. An ultrasonic generator turns power into 18–21 KHz alternating electrical energy and sends it to the transducer.

Crushing ultrasonic instrument Type

An ultrasonic generator and a transducer make up a cell disruptor (some are equipped with a sound insulation box). Ultrasonic generators use frequency-specific signal generators. It’s the transducer’s frequency. 20 KHz, 25 KHz, 28 KHz, 33 KHz, 40 KHz, and 60 KHz are common ultrasonic frequencies. The transducer and horn form the transducer assembly. The soundproof box reduces noise and keeps the lab quiet.

Power classification

Ultrasonic output powers that are commonly used include 150W, 250W, 650W, 1000W, 1200W, and 1800W.Ultrasonic crusher power ranges from 150W to 1800W.

The ultrasonic cell disruptor‘s crushing capacity is 0.5-500 ml, 0.5-600 ml, 10-100 ml, 50-1000 ml, 550-1200 ml, and the crushing cup is chosen based on the amount of experimental samples. Models vary in crushing power. Most ultrasonic power outputs above 650W have a temperature control feature to keep them from getting too hot.

The customer’s favorite indicator of ultrasonic cell disruptor strength is broken object quantity, size, quality, and effect. Scientific research units like laboratories, research institutes, and drug inspection institutes consume less electricity (typically below 500W) than production units like biological firms, pharmaceutical factories, and chemical companies. 500W-2000W is typical.

Different manufacturers’ power marking methods reflect their product architectures. Users commonly utilize 50w, 100w, 150w, 250w, 300w, 350w, 500w, 1000w, and 2000w. Ultrasonic cell disruptors have adjustable output power. Ultrasonic cell pulverizers run at 20 kHz. Some ultrasonic cell disintegrators have an automatic frequency-tuning mechanism.

Probe diameter

Different sample volumes require different sonicator “tips.” Different manufacturers’ product structures affect the “tip” head’s diameter. The “tip” head ranges from a tiny 5mm (ideal for 1ml processing volume) to a 25mm (suited for 1000ml processing volume), and the processing volume can exceed 80 liters/hour. In high-energy applications, replaceable “tip” tips are used. Energy released through the “point” causes corrosion on metal surfaces.

Corrosion pits over time. The “tip” head can be sanded with sandpaper or gauze unless it is broken; when this happens, it will have trouble tuning the frequency and may make a long, loud noise and crack. For efficient sample processing, “tip” size and output power are key. For optimum outcomes, pair these two criteria. If the power is modest and the “tip” head is huge, the “tip” head won’t work, and too much power may harm it. Please purchase model-specific accessories.

Application

Ultrasonic dispersion of cosmetics

Ultrasonic emulsification can be used to extract the drug’s essence and miniaturize the particles, saving production costs, achieving dispersion and emulsification, and making cosmetics penetrate deeper into the skin’s inner layer, enabling the skin to absorb well and exert the drug’s efficacy and effect. Idealize Ultrasonic dispersion can disperse small oil particles without an emulsifier. Paraffin distributed in water can be below 1 mm.

Pharmaceutical Ultrasonic

1) Dispersion of pharmaceutical substances for injection: Mix phospholipids and cholesterol with drugs in an aqueous solution the right way, and then use ultrasonic to break up the mixture into smaller pieces that can be injected intravenously.

2) Herbal Extraction: Using ultrasonic dispersion to damage plant tissue, increase solvent penetration, and improve herbal medicine extraction. Ultrasonic dispersion, on the other hand, may be able to reach all of the alkaloids in cinchona bark in half an hour.

3) Preparation of suspension-A solid pharmaceutical is dispersed in an aqueous solution containing surfactant to generate a 1 um suspension for oral or intravenous administration.

A vaccine is prepared after ultrasonic dispersion kills the cells or germs.

Alcoholization of wine by ultrasonic waves-aging technology

People like fine wine’s mellow taste, smoothness, and deep scent. Wine is controlled by the production of acid and esterification. Ester binds ethanol and water. Newly-made wine is alcoholic and peppery. This smell will take a long time to go away. Slowly, the wine alcoholizes. Ultrasonic treatment at 1.6KW and 17.5-22 KHz for 5-10 minutes can cut wine aging time in half.

Ultrasonic nanometer extraction

In ultrasonic chemical reactions, sound wave cavitation is crucial. During ultrasonic wave irradiation, liquid bubbles form, expand, and collapse. Covering forms when cavitation bubbles collapse. Strong ultrasonic pressure pulses produce high temperatures up to 5000K and pressures above 200Mpa. Ultrasonic chemical synthesis uses this energy. Using these energies, nanoparticles can be produced in powders.

Lysis, fragmentation, leaching, animal DNA extraction, protein extraction, DNA/RNA trimming, chromatin immunoprecipitation for bacteria, viruses, spores, and other biological structures.

Material chemistry: disintegration, emulsification, homogenization, and crushing of nanoparticles, including carbon nanotubes, graphite, selenium, and other materials.

Ultrasonic cell pulverizers are employed in biochemistry, microbiology, pharmacology, physics, zoology, agronomy, medicine, and pharmaceuticals.

Use

Before we can use the ultrasonic mill, there are a few things we need to know.

1. Insert the ultrasonic horn before turning on the instrument to prevent no-load damage.

2. The horn probe should be submerged between 1 and 2 cm, the liquid level should be above 30 mm, and it should not be hooked to the center wall.

Setting ultrasonic parameters

1) Use ultrasonic for a short period of time and several times. The time that the ultrasonic waves are on should be less than 5 seconds, and the time between waves should be longer so that heat can escape.

2) Ultrasonic power shouldn’t be too high to prevent sample splashing or foaming.

If the sample volume is less than 10ml, the power should be less than 200W, and a 2 mm ultrasonic probe should be used (the power of a small 2 mm probe cannot exceed 350W).10-200ml sample capacity, 200-400w power, and a 6mm ultrasonic probe; More than 200ml sample capacity, 300-600w power, and a 10mm ultrasonic probe are used (the power of the small probe of 2 mm cannot exceed 350W).

3) Choose a crushing cup based on sample size (or a beaker); Parameter example: 300W, 70 times, ultrasonic for 5 seconds, interval for 5 seconds: 100ml E. coli sample (total time is 10 minutes).

Ultrasonic cleaner vs. crusher

Ultrasonic cleaners and cell disruptors use similar concepts. The ultrasonic cell disruptor concentrates all its energy on the probe, while the ultrasonic cleaner distributes it equally across the tank’s bottom. Ultrasonic cleansers degas and clean, whereas ultrasonic cell disruptors disrupt, emulsify, and homogenize.

Can an Ultrasonic Crusher be used to Separate Organelles?

Most of the time, ultrasound has thermal effects, cavitation effects, and mechanical effects on cells. The thermal effect occurs when the frictional force slows the ultrasonic wave’s molecular vibration, converting some of the energy into local high heat (42-43 °C). Under ultrasound, vacuoles form in the organism and implode violently, causing mechanical shear pressure and turbulence.

When the cavitation bubble ruptures, high temperatures (approximately 5000 °C) and pressures (up to 500104Pa) are formed, which can thermally dissociate water vapor to generate OH radicals and H atoms, which can lead to polymer degradation, enzyme inactivation, lipid peroxidation, and cell death. Ultrasound is primarily mechanical. During ultrasonic propagation, medium particles alternately compress and stretch, producing cell injury. How bad the injury is closely related to how often and how strong the ultrasound is.

Therefore, ultrasonography breaks cells’ internal structures. Sonication is used to disrupt E. coli inclusion bodies to overexpress target proteins. From the viscosity of the liquid, we may tell that the DNA inside is disrupted by the ultrasonic disrupter, transforming from an ultrastructure to a linear structure (thus the liquid becomes viscous). High intensities and frequencies disrupt organelle structure during organelle separation.

Summarize

Ultrasonic disruptors shake and burst cell suspensions with ultrasonic waves. This approach works best with microorganisms. Escherichia coli is used to make a wide range of enzymes. High-intensity ultrasonic waves at 15-20 kHz can damage cells. Cavitation’s shock wave and shear force may be responsible for its crushing mechanism. Sonic frequency, energy, treatment period, cell concentration, and main type affect sonication efficiency. Ultrasonic technology has both benefits and drawbacks.

Benefits: It’s easy to use, easy to repeat, and saves time. Most of the time, it’s used to break up microorganisms and tissue cells.

Issues: Ultrasonic crushing is often used in laboratories. Ultrasonic waves can denature and inactivate some sensitive active compounds, although they are easy to use and lose little liquid volume. Large-capacity devices have trouble transmitting sound and dissipating heat, so they need cooling, and should be used with care if they are sensitive to ultrasound or nucleic acids. Cavitation is the direct cause of cell death. At the same time, reactive oxygen species will be formed, so sulfhydryl agents should be added to protect the cells.