Animal Tissue Grinding Vs. Plant Tissue Grinding Machine:What is Difference?

What Is the Difference Between a Cryogenic Tissue Grinder And Other Cryogenic Grinders?

Cryogenic tissue grinders and basic cryogenic grinders are widely used in selecting sample grinding equipment. They can be utilized for grinding in multiple ways. Additionally, the pulverization of sample tissues that are difficult to grind can also be achieved. But the critical question is, what’s the difference between the two?

Cryogenic grinding instruments exhibit improved kinetic energy rates and better grinding speed and effect than conventional grinding instruments. During sample grinding, the sample becomes brittle as pulverization is done at ultra-low temperatures. Consequently, samples exhibiting challenges at grinding can be ground easily.

When grinding a sample tissue by the cryogenic tissue grinder, the sample is submerged in liquid nitrogen for pre-cooling, making it brittle and easy to break. The breaking time of the sample is reduced to less than a few minutes. The secret for sample grinding is hidden in exposing the sample tissue to ultra-low temperature with the help of liquid nitrogen. Due to their high flexibility, sample tissues such as polymers, rubber, particles, hair, nails, skin, and bones are difficult to grind. However, pre-treatment with nitrogen makes the process easier.

Cryogenic grinding plays an essential role as a pre-treatment method in the analysis of chemical samples. Most analytical samples with a soft or sensitive physical state at room temperature decompose quickly into different forms during the grinding process. Therefore, pre-treatment with liquid nitrogen to achieve ultra-low temperature is an alternative approach to minimize this phenomenon.

Both cryogenic tissue grinder and cryogenic grinder offer ultra-low temperatures for sample tissues but the grinding methods developed are relatively different. The fineness of the sample after grinding will vary for various types of grinding equipment. Before selecting, it is necessary to check whether the grinding fineness is within the required range.

What is the difference between dry and wet grinding of multi-sample tissue grinders?

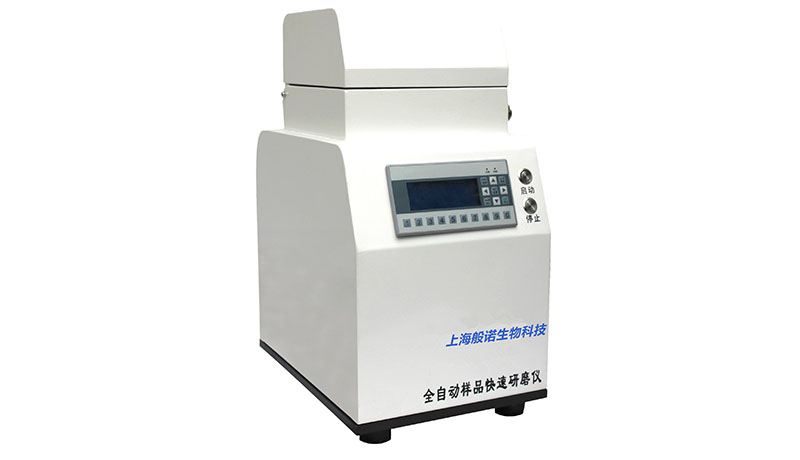

The multi-sample tissue grinder was developed for modern laboratory applications with a grinding time of 45 seconds. The instrument can simultaneously process two or more samples with a sample volume of 0.2–100ml. Additionally, it offers dry and wet grinding methods; however, the interest lies in the difference between them.

Dry grinding refers to the grinding of the sample in dry form. No organic solvent is required during the entire process, and raw material can be ground directly without any external help. The location and operating pressure of the pestle are changed following various samples as the sample is continually extruded and rubbed between the rotating mortar and pestle after entering the mortar from the feeding port.

Wet grinding refers to the grinding of the sample in a wet form which is achieved by adding organic or inorganic solvents. Grinding aids usually include anhydrous ethanol, organic solvents, and ultra-pure water.

How does a high-throughput tissue grinder work?

A symmetrical set of high-speed, large-amplitude rocker arms is part of the high-throughput tissue grinder. The sample can be quickly ground, crushed, and rubbed by the random impact and friction of tiny balls or stainless steel beads inside the sample tube in a few seconds to several minutes.

How to use a high-throughput tissue grinder

- Plug the power supply and place the instrument in a well-ventilated, dry area. Closely observe the control display lights of the instrument. Turn it on and test the control buttons to see if they usually work. The instrument should not make any concerning sounds.

- Transfer a suitable amount of sample with grinding balls into the ball mill. Do not over-fill it. The sample and grinding balls should occupy one-third of the volume during the initial grinding.

- If pre-freezing seems essential, the sample in the ball mill jar should be treated with liquid nitrogen for at least three minutes and then loaded for grinding.

- Put the ball mill jar into the fixture of the high-throughput tissue ball mill. Slowly turn the runner, fix the ball mill jar with the automatic center positioning fastening device, and cover the lid.

- On the control display, set the grinding machine’s swing frequency and running time, and then begin grinding. Turn the wheel to remove the ball mill jar after grinding.

What is the difference between animal tissue grinding and plant tissue grinding?

Molecular biology experiments require the grinding of tissue samples such as connective tissue, animal muscle tissue, bone tissue, hair tissue, etc., to break them down into their components for extensive analysis. The biological samples are quickly frozen with the help of liquid nitrogen to seize all reactions inside and outside the cell, along with protecting the tissue and extracting RNA and DNA easily.

- Animal tissue grinding (homogenization): Add 1–2g of sample in a 15ml short grinding bottle. Place the grinding bottles in a freezer and pre-cool in liquid nitrogen for 10 minutes. Grind after pre-cooling treatment. The grinding speed is set to 1500rpm for 2 minutes. If the sample is cold, pre-freeze the vial in liquid nitrogen before loading the sample into the vial.

- Plant tissue grinding (decomposition): Add 50mg of sample in a 2ml grinding jar. Place the jar in a 2ml foam rack or a 96-hole deep well with a 4mm grinding steel balls plate. Set the speed to 1500rpm for 1 minute. The addition of lysis buffer depends on the user method.

What are the Main Factors Affecting the Quality of Plant Tissue Grinder?

The uniformity of the grinder wear is crucial as uneven wear of the grinder will change the flatness of the multi-sample tissue grinder. Hence, uneven grinding pressure will be produced, and the flatness of the workpiece will not be up to the processing standards. Good uniformity can ensure that workpieces processed for a long time in batch processing have better surface accuracy.

The degree of wear of the grinder can affect the service life of the multi-sample tissue grinder. To protect the instrument’s service life, the cutting speed can be increased as it will not affect the accuracy. Material removal rate will also be increased, which reduces the grinder’s wear.

Several common sample tissue grinding methods:

Choosing the right grinding bottle and media is critical for handling different samples. A more powerful grinding medium is recommended for complex samples such as bones. Some softer samples such as bacteria and fungi are available with 400–600 micron silica beads, prefilled grinding bottles, or separate grinding bottles and grinding media. The animal and plant tissue grinding methods are described previously. The rest include:

Fruit Grinding (Extraction): Pesticide Residue Extraction: Take 15gm of sample and transfer it into a 50ml centrifuge tube. Take two large ceramic columns and put them into a 50ml sample holder. Grind it on the machine. Acetonitrile is a common solvent for the QuCHERS method.

Vegetable Grinding (Homogeneity): DNA/RNA Extraction/Pesticide Residue Extraction/Gene Trait/Expression: Add 15gm of sample to a 50ml or 15ml grind jar. Add ceramic column and steel balls and grind on the machine. The grinding speed is set at 1500rpm for one minute.

Seed Grinding: DNA/RNA Extraction/Protein Extraction/Carbohydrate Extraction:

Add one seed to a 2ml grinding jar. Place the jar in a 2ml foam rack or a 96-well deep well plate with 4mm grinding steel balls. Grind on the machine. The grinding speed is set at 1750 rpm for two minutes. Lysis buffer is added as per the user method.

Insect sample grinding: DNA/RNA extraction: A 2ml grinding jar should be filled with one insect leg before being placed in a 2ml foam holder. Set the machine to grind, with a 2-minute grinding cycle at 1750 rpm. Lysis buffer is added as per the user method.

Grinding of food samples (grains such as corn, rice, feed): protein extraction/carbohydrate extraction: 2 11mm steel balls and 1–2g of the sample should be added to a 15ml short grinding bottle. The grinding bottles are put in a freezer box and given a 10-minute pre-cooling in liquid nitrogen. Use the machine to grind after pre-cooling. The grinding time was 5 minutes, and the speed was 1500 rpm.

An alternative method of rice grinding: Add 2–3 grains of rice into a 96-well deep-well plate, then add a 4mm steel ball. Grind on the machine. If deep-well plate freeze grinding is required, the 2650 freezer adapter should be placed in liquid nitrogen to cool down sufficiently and inserted into the 2210 deep-well plate for use.

Bacterial fungal cell lysis: DNA/RNA extraction: Add sample to a 2ml prefilled vial and place it in a 2ml foam sample holder. Grind on the machine. The grinding speed is set at 1000cpm for 30 seconds. Extraction solution or buffer should be added during extraction.

Tooth: DNA/RNA extraction

2 11mm steel balls and 1–2g of the sample should be added to a 15ml short grinding bottle. A freezer box was used to hold the grinding bottles after they had been pre-cooled in liquid nitrogen for ten minutes. Use the machine to grind after pre-cooling. The grinding time was 5 minutes, and the speed was 1500 rpm.